-

+Free delivery (DPD) from 800,- €

?

By order under 800,- € we charge 26,- € shipping costs.

LEKI Race poles WC Racing Comp Lite Junior

Anyone who has seen the bright red pole with the yellow neon flash racing into the valley at a World Cup race knows that many top athletes from different national teams trust LEKI. This pole is for young athletes who want to emulate their idols.

The Trigger S Compact grip with the new Frame Strap with elastic element provides the ultimate grip and automatically releases when falling to minimise the risk of injury in the arms and shoulders. The high-quality carbon composite material and the slim 14/12 shaft ensure optimum swing action and precise pole use.

Procut classification

| For whom: | Junior |

| Use of poles: | Allround |

| Material of ski poles: | Aluminium, Carbon composite |

| Adjusting the length of the poles: | No |

| Type of basket: | Standard |

| Clamping system: | Leki Trigger S |

Technologies

-

TRIGGER S

Maximum security, outstanding comfort. Click your straps in and out faster and more comfortably than ever before with Trigger S.

The patented security release can offer additional protection against injury.

Check it out!

01 Click-in - Fast and simple click-in with the Trigger Loop

02 Click-out - Fast and simple click-out with the Trigger Loop

03 Trigger Loop - LEKI gloves with Trigger S and Trigger Shark provide maximum comfort and security. Easily click the strap into and out of the pole with Trigger Loop

04 Powerframe - The complete strap is built into the glove so that only a small loop made of very flexible and extremely tear-resistant material, comes out of an opening in the palm of the glove

05 Security spring - The security spring-trigger system releases the strap upwards under strong tensile load. The first ski pole with a built-in safety binding can minimise fall injuries

06 Correction zone - Integrated + 8° grip correction zone for optimal pole holding position

-

ALUMINIUM HTS 5.5

Very solid aluminum pipes are hardened by a special process developed Leki, thereby gaining these sticks highest stability and optimum properties to resist in extreme conditions. Hardened Leki crosscountry poles are mainly designed for sports hobby runners and beginners, who need greater certainty of stability before the eventual fall.

-

CARBIDE TIP

For precise pole planting and uncompromising grip on any surface

-

FRAME STRAP

- Optimized fit: encloses the hand securely

- Wide shape

- One Piece – 360° inner hand – no overlapping material

-

POWER TRIGGER (Shark + Trigger 1) S-M-L

- S-M-L (Veľkosť 5-9)

- Maximum comfort, superior power transfer, and easy handling

- Click your straps in and out in seconds with Trigger Shark

-

SL GRIP

Slalom Grip

-

ADAPTER CAP

Enables assembly of LEKI Gate Guards the LEKI GoPro™ Compatible Adapter.

-

COMPACT GRIP

Compact ergonomic handle with bottom stop

-

FLEX TIP ALPINE

More precise pole use and perfect grip on snow and ice

-

JUNIOR

Suitable for juniors.

-

ULTRA SONIC

- Highly durable surface finish

-

MATERIAL

LEKI is the only pole manufacturer that pre-grinds all shafts to ensure optimal pretreatment for further machining steps. Shafts are degreased and cleaned in a chemical-free, environmentally friendly manner. LEKI offers various methods for treating pole surfaces, which are all refined by the final sealing process.

01 Aluminium

LEKI's top poles use only high-strength aluminium shafts (as those used in aircraft construction) and refuses other, possibly more cost-effective material qualities. These are prepared and cured through a process specially developed by LEKI. Shafts processed this way deliver superior stability to withstand extreme conditions and applications. It is thus no surprise that LEKI's high technology standards result in long-lasting and durable shafts and designs. LEKI quality is legendary!02 Carbon

Carbon fibres result from complex carbonization processes of synthetic polymer fibres or organic substances. These processes yield a fibre mesh that is approximately eight times thinner than a human hair. In turn, carbon fibre shafts presents an extremely high stiffness and bending capacity with very low specific weight.03 Innovative painting process

LEKI contributes to the protection of the atmosphere by using water-based paint systems and introducing emission-free powder varnish technology. The use of high-tech painting systems and sophisticated paint circulation solutions allows for the near-full recycling of all coating materials used. All processed coatings and printing inks are free of compounds containing heavy metals and harmful AZO dyes.

Wet paint method

Several layers of paint are applied to the prepared shafts. The surface is thereby sealed and protected.

Powder coating Powder is applied in several layers by means of nozzles onto the shaft, baked at high temperatures in the oven, and then dried.

Anodic coating

In this coating technique, aluminium shafts undergo a chemical process. The result is a high-quality, super resistant, and virtually scratch-free surface.

Technical description

-

Upper Section

Aluminium (HTS 5.5) -

Lower Section

Carbon Composite -

Handle

Trigger S -

Strap

Trigger S Frame Strap -

Diameter

14|12 mm -

Saucer

50 mm -

Tip

Flex Tip Alpine -

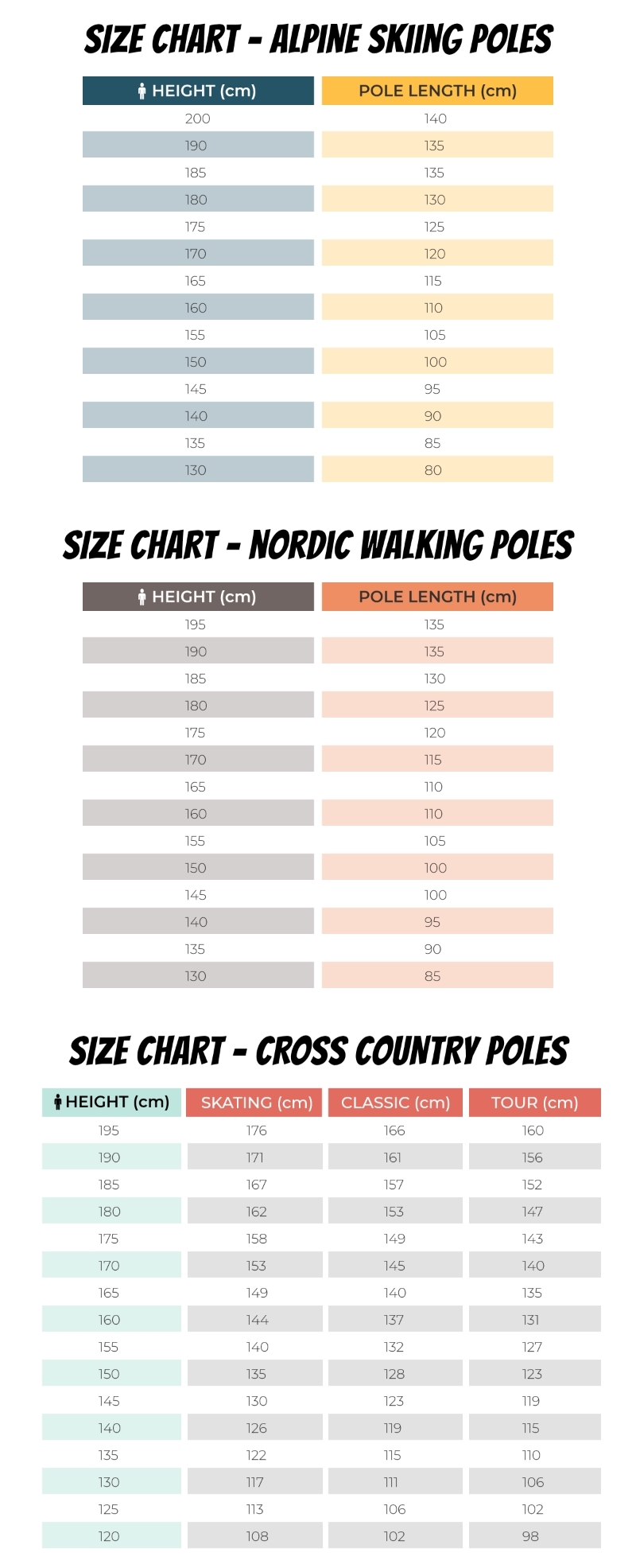

Length

90 - 120 cm -

Weight

226 g (105 cm) -

Product code

6436520

Other

-

Product code

N18001858

More information

More information Privacy Notice

Privacy Notice