-

+Free delivery (GLS) from 800,- €

?

By order under 800,- € we charge 26,- € shipping costs.

-

+

Ticket for chair lift for free x2

?

- chair lift Serrada (Alpe Cimbra)

- Chair lift Harrachov

LEKI WCR Lite SL 3D

- Racing poles with Airfoil technology and new TRIGGER 3D technology

From the top World Cup Racers to skiers sut learning, confidence and control play an inportant role in skiing. Thanks to the new TRIGGER 3D, LEKI has achieved a quantum leap in this regard. The fit and feel are crucial for precisely controlled pole usage. 3D Trigger provides perfect pole handling with direct feedback to the skier.

Hours of desing process went into the ergonomic desing of the grip. For the Trigger 3D, product developers focused on the outline and shape, paired with materials and textures for a streamlined look and feel that is focused on performance. The result? A newly designed grip head area, allowing for increased comfort when clicking in and out of the Trigger 3D System.

The new Trigger 3D poles can be used with all Trigger S gloves and straps. With an eye toward sustainability, LEKI focused on creating the new Trigger 3D Grip without rendering old Trigger S obsolete.

- Strap size S-M-L

Procut classification

| For whom: | Junior |

| Use of poles: | SL |

| Material of ski poles: | Aluminium |

| Adjusting the length of the poles: | No |

| Type of basket: | Standard |

| Clamping system: | Leki Trigger 3D |

Technologies

-

ADAPTER CAP

Enables assembly of LEKI Gate Guards the LEKI GoPro™ Compatible Adapter.

-

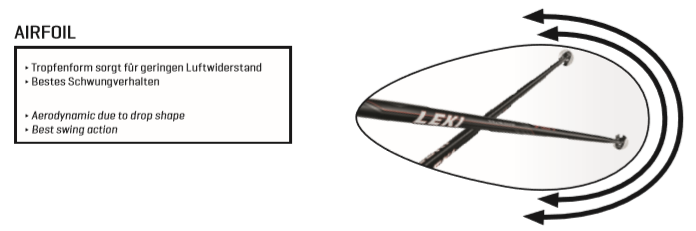

AIRFOIL

- Drop-shape profile of poles

- Transferred technology from the aviation industry

- Minimum air resistance, aerodynamic shape

- Better stability in bend

-

ALUMINIUM HTS 6.5

- Super stable, extremely robust and very durable

-

CARBIDE TIP

For precise pole planting and uncompromising grip on any surface

-

COMPACT GRIP

Compact ergonomic handle with bottom stop

-

JUNIOR

Suitable for juniors.

-

MATERIAL

LEKI is the only pole manufacturer that pre-grinds all shafts to ensure optimal pretreatment for further machining steps. Shafts are degreased and cleaned in a chemical-free, environmentally friendly manner. LEKI offers various methods for treating pole surfaces, which are all refined by the final sealing process.

01 Aluminium

LEKI's top poles use only high-strength aluminium shafts (as those used in aircraft construction) and refuses other, possibly more cost-effective material qualities. These are prepared and cured through a process specially developed by LEKI. Shafts processed this way deliver superior stability to withstand extreme conditions and applications. It is thus no surprise that LEKI's high technology standards result in long-lasting and durable shafts and designs. LEKI quality is legendary!02 Carbon

Carbon fibres result from complex carbonization processes of synthetic polymer fibres or organic substances. These processes yield a fibre mesh that is approximately eight times thinner than a human hair. In turn, carbon fibre shafts presents an extremely high stiffness and bending capacity with very low specific weight.03 Innovative painting process

LEKI contributes to the protection of the atmosphere by using water-based paint systems and introducing emission-free powder varnish technology. The use of high-tech painting systems and sophisticated paint circulation solutions allows for the near-full recycling of all coating materials used. All processed coatings and printing inks are free of compounds containing heavy metals and harmful AZO dyes.

Wet paint method

Several layers of paint are applied to the prepared shafts. The surface is thereby sealed and protected.

Powder coating Powder is applied in several layers by means of nozzles onto the shaft, baked at high temperatures in the oven, and then dried.

Anodic coating

In this coating technique, aluminium shafts undergo a chemical process. The result is a high-quality, super resistant, and virtually scratch-free surface. -

POWER TRIGGER (Shark + Trigger 1) S-M-L

- S-M-L (Veľkosť 5-9)

- Maximum comfort, superior power transfer, and easy handling

- Click your straps in and out in seconds with Trigger Shark

-

TRIGGER 3D

SECURITY - COMFORT - CONTROL

- Better control due to direct connection between glove and pole

- Improve ease of use due to fast and easy in and out

- Maximum release range thanks to intelligent Trigger 3D system

- Release Spring System: + Release spring doses three dimensional release force

- Four finger notches/Integrated grip lines: + Comfortable grip position without slipping

- Rubberuted contact zone: + Non-slip rubber material for maximum control

- Trigger release button: +Easy click out by pressing down the button

- Trigger 3D Hook:+ Maximum release range thanks to intelligent Trigger 3D System

- Positive Angle 8° :+Supports natural movement and protects the wrist

-

ULTRA SONIC

- Highly durable surface finish

-

TRIGGER 3D SL GRIP

The Trigger 3D SL is equipped with the Trigger System. Thanks to its finger indentations, the poles fit perfectly in the hand. Its special shape makes it the ideal slalom grip.

Technical description

-

Material

Aluminium (HTS 6.5) -

Construction

Fixed length -

Handle

TRIGGER 3D SL -

Strap

Trigger S -

Diameter

16 mm Airfoil -

Saucer

Alpine (Racing) -

Tip

Carbide Tip -

Length

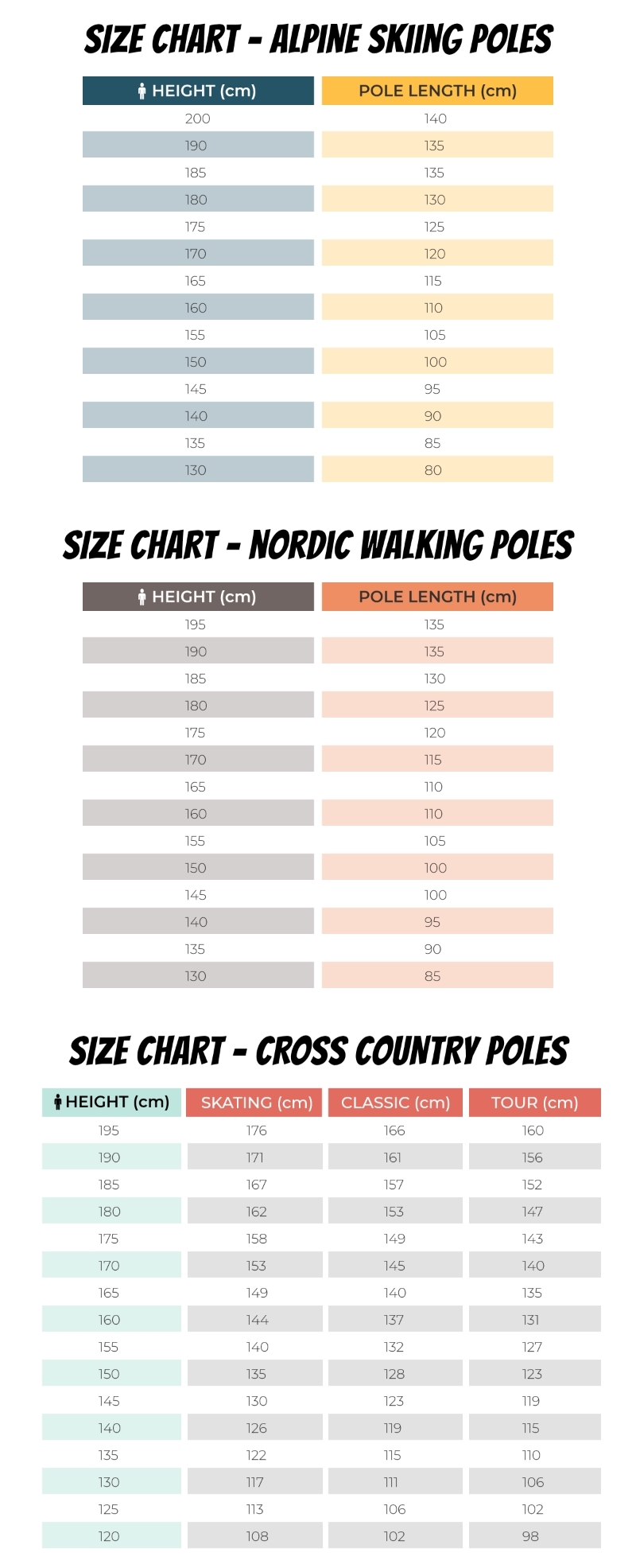

90 - 120 cm -

Weight

234 g (105 cm) -

Product code

65065851, 65065852

Other

-

Product code

N20001906

More information

More information Privacy Notice

Privacy Notice